Over the years our customers have asked very insightful questions about the field of particle size and image analysis, the following list of questions are a selection of the most frequently asked. If there is a question that is not answered here, please contact us.

What are the benefits of a particle image analyzer?

Analytical methods like image analysis can be powerful tools in revealing more about particles, for example their size and shape and in turn their behavior in terms of end product quality. In fact, measuring shape is one of the major benefits Image analysis has over other light scatter-based technologies. Eyecon2 is a smart particle image analyzer that combines the advantages of microscopy and digital particle analysis and enhances them. Eyecon2 measures particles from images in real-time by taking hundreds or thousands of measurements per image and reporting particle size and shape automatically, this digital information can then be communicated over protocols like OPC to not just report the particle size and shape but to control it. Eyecon2 is used in production environments to monitor and log product quality digitally and in R&D environments to investigate the changing process parameters like RPM, airflow, temperature, etc. have on particle size and shape in real-time.

What does non-product contact mean?

Non-product contact means Eyecon2 is not in direct contact with the product it is measuring. It is a camera-based system that when mounted in-line is typically looking through a process window at a distance ranging from 0-25mm away from the product. Because of its non-product contact nature, it requires less change control to install into a controlled environment as it poses less of a risk to the product. The non-product contact allows Eyecon2 to measure products in hazardous ATEX zones. Plus, non-product contact does not interfere with the process itself, potentially modifying the particles it is measuring.

What size ranges can the Eyecon2 measure?

The Eyecon2 can measure bulk solids between 50µm – 5500µm

Which industries benefit the most from particle size analysis?

Any Industry where bulk solids particle size and shape advances end product quality, quantity, and the bottom line. Hence Eyecon2 has seen mass adoption in pharmaceutical manufacturing. Other Industries Eyecon2 is sold into include:

Chemical, Mining, Food & Feed, Construction, Energy. Because it is a smart particle image analyzer it can instantly digitally transform industries that log sieve analysis via pen paper methods to benefit from automated particle size analysis.

Can particles in liquids be analyzed?

No, Eyecon2 is not suitable for measuring materials that are suspended in liquid due to a few reasons, particles in a medium when looked at with a camera change in size due to the light path and magnification effect of the medium. Eyecon2 is designed to measure wet solids such as materials wetted in a fluid bed coater or twin-screw granulator.

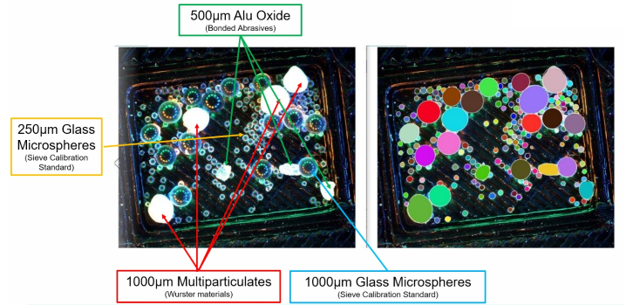

What capabilities of Machine Learning will benefit particle image analysis?

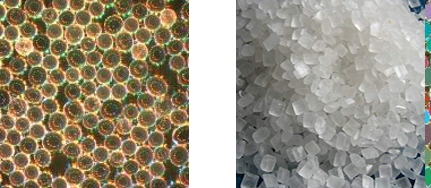

Incorporating Machine Learning into particle image analysis has revolutionized the capability of

Eyecon2 . You can now measure entirely new material types such as glass beads, crystals, Urea,

Oxides, among others. This expands not only capability but flexibility for future developments in

image analysis.

An overview of how machine learning works in conjunction with Eyecon2 can be reviewed here.

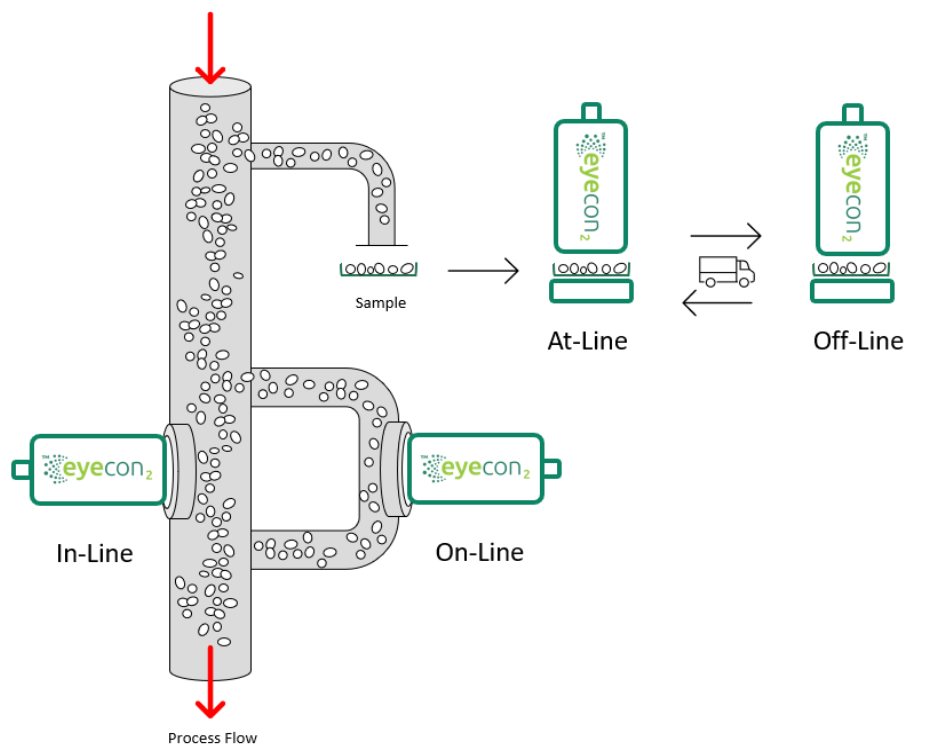

What is the difference between At-line, Off-Line, On-line, and In-line?

At-line analysis involves the analytical device being located near the process where a sample

from the process line is rapidly analyzed.

Off-line analysis involves the analytical device being located away from the process line where it

was produced. It means sending a sample to either an on-site or off-site laboratory for

analysis.

On-line analysis involves the analytical device being located on the process line, where the

product is being passed by the analytical device, typically via a type of bypass valve.

In-line analysis involves the analytical device being located in the process line itself, for direct

measurement right where the product is being made so there is little to no risk of sampling

error.

A simple way to differentiate At-line, Off-Line, On-line, and In-line is to add the word “the” in the

middle. So, At-line means the measurement happens ‘at the line’. Off-line means the

measurement happens ‘off the line’ and so forth. On-line and In-line are often confused a simple

way to distinguish between the two is to ask, ‘is the product being brought to the analytical

device? (On-line), Or is the analytical device being brought to the product? (In-line)’.

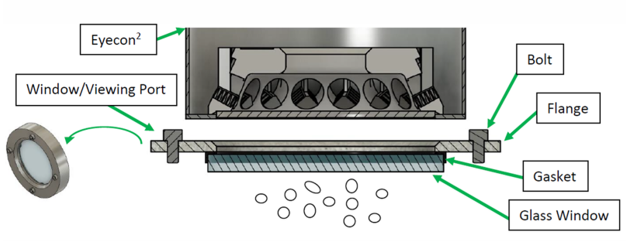

How can an in-line particle analyzers be integrated with process machinery?

Eyecon2 is a non-product contact device. It is a camera-based technology and will either view

through a window or onto a chute to measure particles. Integration in-line can be via a simple

bracket, or it may require a more complex integration solution for example it may require an

anti-fouling mechanism or have a new window fitted into a process. As important a question to

‘how can it be integrated?’ is to ask ‘where’ it should be integrated? because analyzing

representative product is key to reliable results. Innopharma Technology has over 10 years of

experience installing devices in-line. We offer 'off the self' solutions as well as the expertise to

design, fabricate and integrate a solution suitable to your process needs. Please see below a

selection of various in-line integration solutions.

How can I find out more?

The best way to get in contact is through the 'Start a Conversation' enquiry at the bottom of this

page so we can arrange a call together and find out more about your needs for particle

analysis.

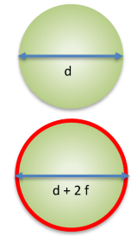

Can Eyecon2 measure non-uniform shaped material?

Eyecon2 can measure non-uniform materials such are granular shaped materials. Regardless of

the particle profile, the 2D area of the particle is converted into an equivalent elliptical area and

converted into a 3D spheroid to calculate volume.

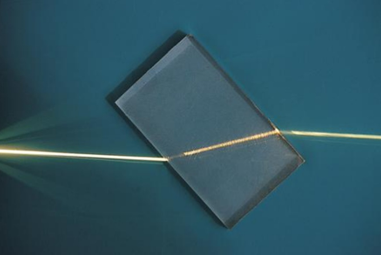

Can Eyecon2 measure materials that are transparent or reflective?

The new machine learning version of EyePASS V3.0 can accurately measure transparent or

reflective materials thanks to trained machine learning models deployed to run in real-time in the

software.

What distance can Eyecon2 be away from the material?

Eyecon2 operates very much like a digital microscope. For at-line analysis, this distance is fixed

by mounting Eyecon2 onto the benchtop Autostage. For In-line integration, It has to be precisely

located between 0-25mm away from the material depending on factors such as the process

window's glass thickness. This distance can be calculated, and an integration solution offered

after a conversation with Innopharma Technology.

Can Eyecon2 detect a change in coating thickness during a coating process like Wurster?

Yes, the coating thickness or film thickness can be derived by subtracting the starting particle

diameter from the current particle diameter and dividing by 2. As the material is being coated

the Eyecon2 will detect a change in a particle size and show it in real-time. Please refer to our

application note titled Real-Time Prediction of Polymer-Coated Multiparticulate Dissolution

using Process Analytical Technology for more information.

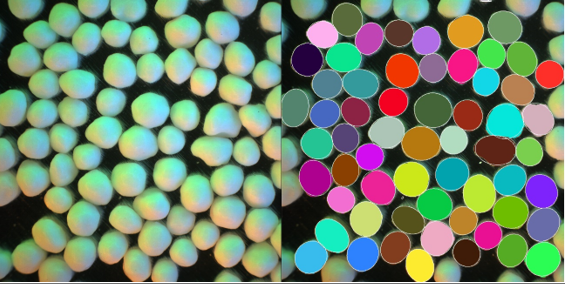

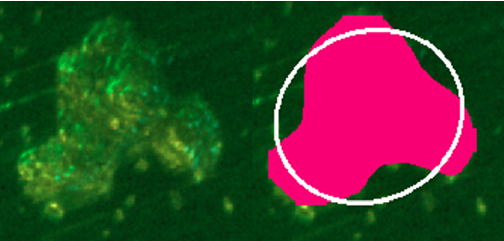

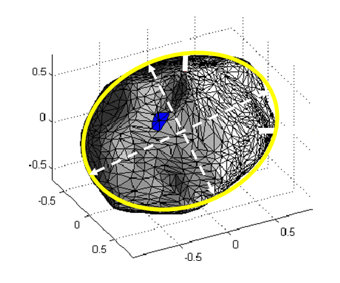

When measuring particles, how is the boundary of each particle defined?

In particle image analysis, the images undergo a pixel segmentation step to determine the

location of the boundary or the edge between the particles' foreground, the substrate

background, and from particle to particle. This segmentation is aided by the unique crossover of

Red, Green & Blue light illumination method from Eyecon2 where the boundary from one particle

to the next can be easily identified when compared to other methods of black-and-white image

processing.

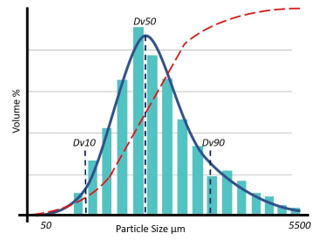

How is the size of the particles calculated in image analysis?

In particle image analysis, after segmentation processing, a major and minor axis are fitted per

particle. The major axis is the longest cord length that can be drawn through the particle and the

minor axis is the shortest cord length that can be drawn through the particle that continues to be

perpendicular to the major axis. The corresponding ellipse is converted into a 3D spheroid to

calculate volume from which when all the particles are calculated together so the D number can

be reported as a distribution or Particle Size Distribution (PSD).

How small a change in particle size can Eyecon2 detect?

Eyecon2 can measure the particle size and shape of bulk solids between 50 and 5500μm. But

when measuring a particle within its size range it can detect a change as small as 5µm. For a

Coating/Wurster process, Eyecon2 can detect growth in film thickness as low as 5µm.

Can 1% of drug loading intervals be detected with Eyecon2 results?

Yes, although Eyecon2 does not directly report the percentage of drug loading, the real-time

particle size data is used together with the loss on weight data of the spray binder from the

balance or scales to calculate the percentage of drug loading. This can be elaborated on in this

study

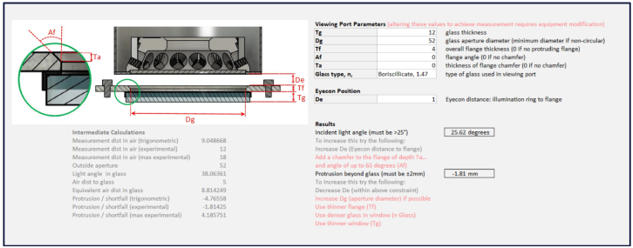

What are the minimum dimensions for a process window that Eyecon2 can be mounted onto?

There are several things to consider when integrating Eyecon2 in-line onto a pre-existing

process window. Such as, are the particles that are presented to the window going to represent

the entire particle size distribution within the process? What is the aperture/size of the window

opening? What is the thickness of the glass? As a guide mounting Eyecon2 requires a window

with a minimum opening of 50mm and a maximum thickness of 20mm. For a free In-line

assessment of your process window please contact us.

What about blocked or fouled windows?

In-line particle image analysis relies on the camera of Eyecon2 being able to capture images of

free-flowing particles. If the material the camera is looking at is not moving, as in the process

window is blocked up with material or ‘fouled’, then no new particles are being presented to the

camera for image capture. This is an issue. Thankfully Innopharma Technology have several

anti-fouling solutions available. These can range from the non-invasive such as a change of

window material to reduce fouling or to the more invasive solutions such as a gas purge

mechanism or wiper mechanism. Get in contact through the 'Start a Conversation' enquiry at

the bottom of this page so we can arrange a call to find out more about your needs.

What ISO standards apply to particle image analysis?

The International Organization for Standardization (ISO) has several standards that apply to

methods of particle measurement. The ISO 13322 series are the applicable standards for

particle image analysis.

ISO 13322-1:2014 Particle size analysis — Image analysis methods — Part 1: Static image

analysis methods

ISO 13322-2:2021 Particle size analysis — Image analysis methods — Part 2: Dynamic image

analysis methods

These two standards go into detail about the considerations around particle measurement via

image analysis with the differentiator between them being one is about static image analysis,

the particles are at rest when images are captured and the other dynamic image analysis,

where the particles are in motion when an image is captured.

Other relevant standards for particle measurement.

ISO 13320:2020 Particle size analysis — Laser diffraction methods

ISO 17867:2020 Particle size analysis — Small angle X-ray scattering (SAXS)

ISO 19430:2016 Particle size analysis — Particle tracking analysis (PTA) method

ISO 22412:2017 Particle size analysis — Dynamic light scattering (DLS)