Before we had any PAT tools, the process was like a black box to us. We put something in and get something out without knowing what happened inside. Now, we have an ‘Eye’ to look inside that black box and see what’s going on in there.

If you’re considering implementing an advanced data platform to optimise your pharma development and manufacturing, our pharma specialists and process engineers will work with you to shape the best technology response. With more insights delivered faster and with ever-increasing automation, we’ll help you achieve the quality, control, efficiency and sustainability you need.

Our SmartX platform provides a fast and clear view of the critical inputs affecting your process.

Refine input parameters quickly and progress with process development in far shorter timescales.

Our SmartX platform, drawing on information from InnoGlobal Technology PAT sensors and other sources, organises data into simple to access, actionable insights.

Adapt the factors impacting on your drug development and manufacturing armed with the process intelligence you need.

We bring complete PAT and process sensor information together and make it view-able through our SmartX dashboard.

Data is aggregated, analysed and visualised smarter and faster, and control decisions are automated. Giving you efficiencies and competitive advantage.

real-time process intelligence for faster, smarter pharma development and manufacturing.

PAT imaging and spectroscopic solutions driven by a team of expert engineers and scientists.

from FP7, EU Horizon 2020 & Enterprise Ireland supporting our unique R&D projects.

to collaborate with industry and academia to progress the future of pharma manufacturing.

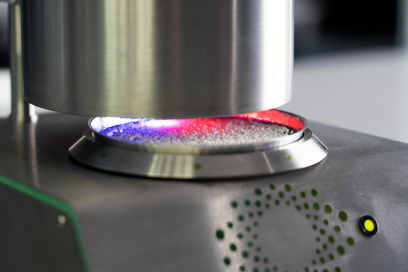

Our accelerated development and advanced manufacturing platform for Fluid Bed Systems. It enables greater process understanding, improvement in efficiency through reduced product variability, and improved end-product quality through automated control decisions…

Our accelerated development and advanced manufacturing platform for Fluid Bed Systems. It enables greater process understanding, improvement in efficiency through reduced product variability, and improved end-product quality through automated control decisions…

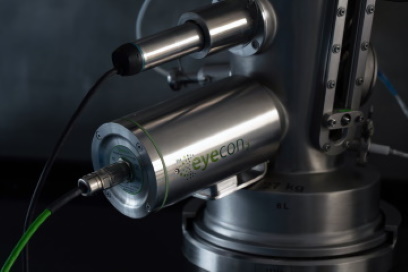

Integration of Eyecon2TM into Alkermes’ centrifugal spheronisation manufacturing processes ensured a more robust analytical method and an 8% increase in yield.

It was in the 1700s that the world saw the first movement in the industrial revolution, and it’s still studied

As the old adage goes “With great power comes great responsibility”. What follows below is an interesting account by our

Over the last decade, manufacturers have been able to reduce waste in and enhance product yield from their manufacturing processes